Guide to choosing a hydraulic lift

Whether you need to lift cars in your home garage or commercial parking or you are looking for a cargo elevator for your warehouse, it’s important to do basic research to understand features and intricacies of various types of lifts to not be let down by slow, noisy, underpowered or downright unsafe lift. The project may seem daunting at first, but our buying guide makes it easy.

A great hydraulic lift will provide convenience, ease of use, stability, safety and long service life.

---- Ancient wisdom.

Do I need a scissor or a post (column) lift?

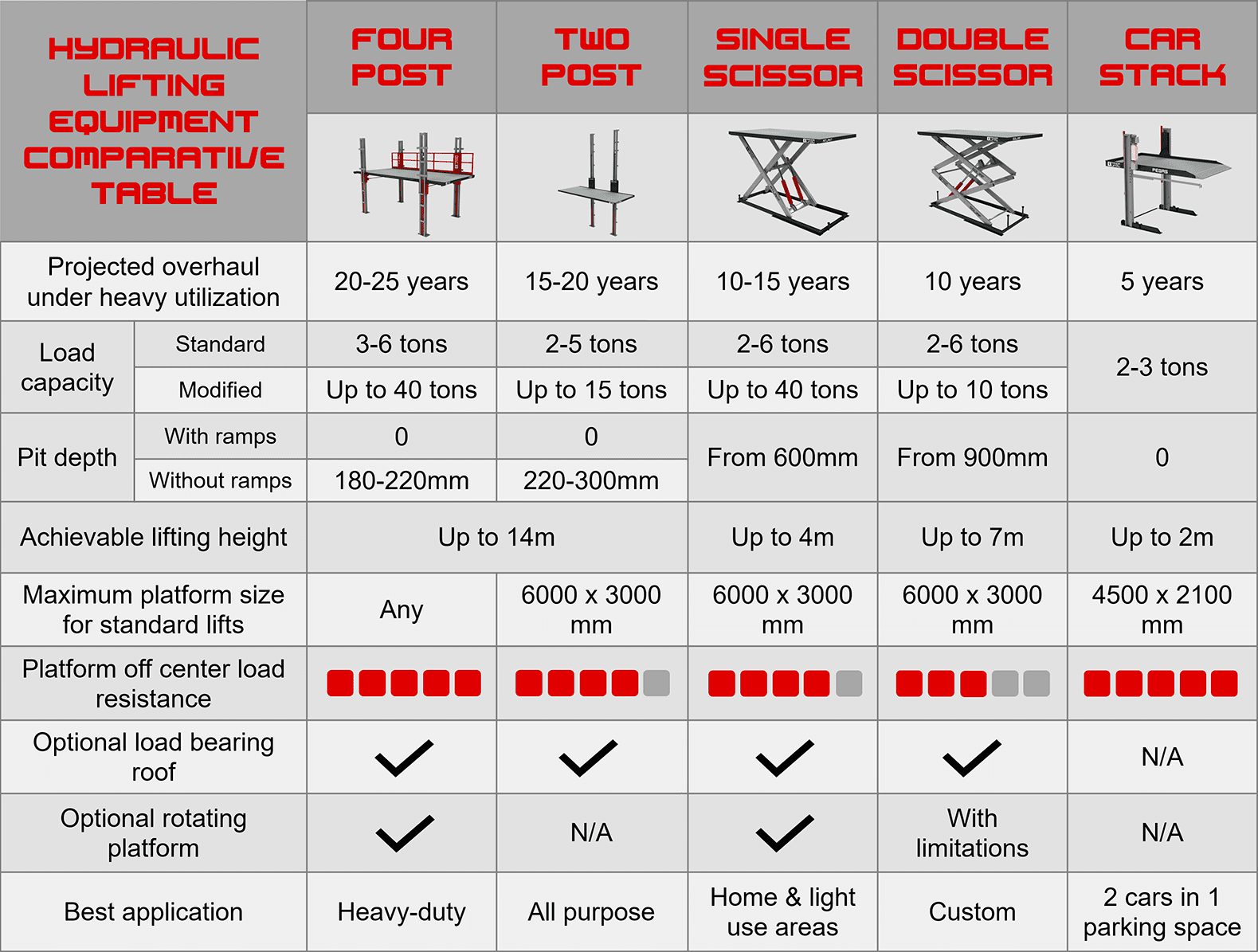

As a rule of thumb, scissor lifts are better suited for home garages, infrequent use cases or light weights, whereas post (column) lifts are more applicable for commercial or heavy utilization such as car showrooms, warehouses, business centers and high capacity parking areas.

How to select among many offers?

Depending on the nature of your requirements there are companies in many European countries, USA, Asia and Australia selling hydraulic lifting equipment of various sizes and shapes to customers worldwide. Selecting lift among them is difficult, especially as they come with the same warranty terms and their product specifications may look similar. But just like choosing a car, specs will not paint the whole picture and you would want to know how long the car will last after its warranty expires.

Sadly, accidents happen because of manufacturing faults: poor quality hydraulic components, cheap, unsafe and inappropriately rated electrical parts, inadequate corrosion protection and in worst case a disregard towards structural integrity.

So just a little technical knowledge will go a long way to make you look past the outside description and understand what you are really getting for your money.

How is it made?

Generally hydraulic lifts consist of several key elements, all of which are important in maintaining required output, constant safety level and aesthetic properties through the lifetime. Let us investigate the most important components below:

Cylinders

Biggest misconception about hydraulic lifts is that the more cylinders the better

Cylinders have limited service life and require periodic maintenance. If one cylinder becomes inoperative, the whole lift will stop working.

Also, more cylinders will likely mean they have a smaller cross section and as a result the internal pressure in each of them is higher which also reduces their working life. Look for lower amount and wider diameter cylinders in the lift design.

In manufacturing, steel skiving & roller burnishing has many advantages over honing. It provides improvements in metal fatigue strength, corrosion resistance, wear resistance of the inner wall and in many other areas. Skiving equipment is expensive so only the top cylinder manufactures can afford it. Ask your supplier how their cylinders are made!

Hydraulic unit

A good, durable, low noise and heat resistant hydraulic unit will have the following properties:

- At the maximum cylinder extension, the hydraulic fluid tank must be at least 50% full. This protects against overheating.

- Quality filters are a must-have to keep hydraulic fluid from contamination.

- For ease of use there should be a filler neck, drain plug and thermometer level gauge.

Main structure

Scissor lift pivot joints should be fitted with self-lubricating high-performance bushings and pins. Together with good quality polymers in sliding assembly, they will prevent wear, leaks, corrosion and importantly, unpleasant, or loud noises from appearing over time.

Sounds made during ascent of a two years old hydraulic lift built without regard to joint lubrication:

Paint and corrosion protection

Hot dip galvanization is necessary to prevent corrosion if you are planning to use your equipment outside. For lifts installed inside buildings a two-component paint should be sufficient. Probably the most overlooked element in low quality manufacturing is the paintjob. Unfortunately, poor paint does not only spoil the look, but also fails to protect against corrosion.

Display panel with call buttons

Most of the time this is purely design consideration, but nonetheless an important one since this will be on the front of your everyday interaction with the lift. They come in various size and forms.

Factor of safety (FoS)

FoS is the number of times system must be stronger than necessary. Good practice requires that any lifting equipment shall have an adequate factor of safety of at least 3 incorporated in its design. This is difficult to verify since this is a design calculation, but as an informed consumer you should at least question your supplier.

Who made it?

Avoid resellers

Some re-sellers will not openly reveal data on the manufacturing plant and its location which gives away that seller may not be the producer. To get the best possible terms and quality assurances always try to look for the manufacturer of the equipment.

Check completed projects

Ask about company’s previous business as real makers are proud of their products and happy to share as much information as possible. Make sure the lifts in photos and videos of those projects feature company’s logo and not just photo watermarks.

Review website

Make sure you thoroughly inspect the website, brochures and product catalogues as you should be able to easily find solid, verifiable information on each topic relating to your lift. Website should be clear, concise and easy to use which would show that manufacturer has paid attention to customers’ comfort.

Warranty and applicable laws

Important to note, that even though most manufacturers will offer a one- or two-year warranty on their hydraulic lift you should check which governing law applies to the purchase agreement and hence to the warranty terms. Many international agreements use laws of England and Wales. Dispute resolution shall preferably be under jurisdiction of LCIA or Stockholm courts. If the worst comes to pass, you do not want to find out that your claim will be governed by a local court in China, under Chinese laws in Chinese language.

Conclusion

Buying a hydraulic lift can be a stressful process, but if you do your homework and learn about the ins and outs of the products, it can become a much better experience. Do your own research and ask questions to your supplier! You will probably own the lift for at least 5 years, and those details you overlook today could come back to haunt you later on. Be an informed customer, ask for and study full technical specifications and carefully evaluate all options. If you followed our buying guide, you probably already have an idea that all hydraulic equipment is definitely not created equal. But don’t stop here, explore more and become confident that you are getting what you really needed.