HYDRAULIC goods lifts

Warehouse, mezzanine lifts for your specific industrial tasks

PANDA LIFT » Goods lifts

Want to know more about our products?

Leave us your contacts and we will get in touch with you shortly:

Let us offer you A goods LIFT THAT FITS YOUR NEEDS

We will send you a quotation by e-mail

Find our what our goods lifts are made of

Safe, reliable and long lasting

We control quality of our goods lifts at every stage of production. Before sending the equipment to customer, we install it at our assembly shop and rigorously test it. This is how we can guarantee long service life and safety of your goods lift.

Safe and smart control system

PANDA LIFT goods lifts are equipped with intellectual control system based on easy-to-program Siemens controllers.

Goods lift may be programmed in accordance with your needs. Control system can be connected to doors or gates, various auxiliary devices (sensors, infrared barriers, light and sound alerts, manual controls, control panels, safety elements etc.).

Unique self-diagnosis mode allows to detect malfunction of electric circuit and goods lift equipment. Detected malfunctions are displayed on control system screen.

Safe manual control

Safety of goods lifts manual controls is critically important. To provide maximum safety to PANDA LIFT goods lifts, manual control panels are made of anodized aluminium or frost-resistant plastic.

Buttons with LED backlight allow the operator to understand the floor where the platform is.

In order to assure safety of operator and other personnel while using goods lift, the following features were provided:

- Low voltage (24V DC);

- LED flashing light to alert about lift movement;

- “EMERGENCY STOP” button;

- Access key to activate manual controls (unauthorized access protection).

Retractable locks provide safety of the personnel on and below the platform.

When stopped on the floor, the platform of the goods lift stays in locked position with locks anchored to lift masts or to mounting wall.

Electromechanical cylinders installed inside the platform retract automatically when lift stops at higher floors, fixing its position. Platform blocks and unblocks automatically and doesn’t require operator actions.

Blocked position of the platform ensures its stability when loading and unloading. Platform always stays aligned with the floor.

Due to safe fixed goods lift platform position operating staff may work safely during loading and unloading.

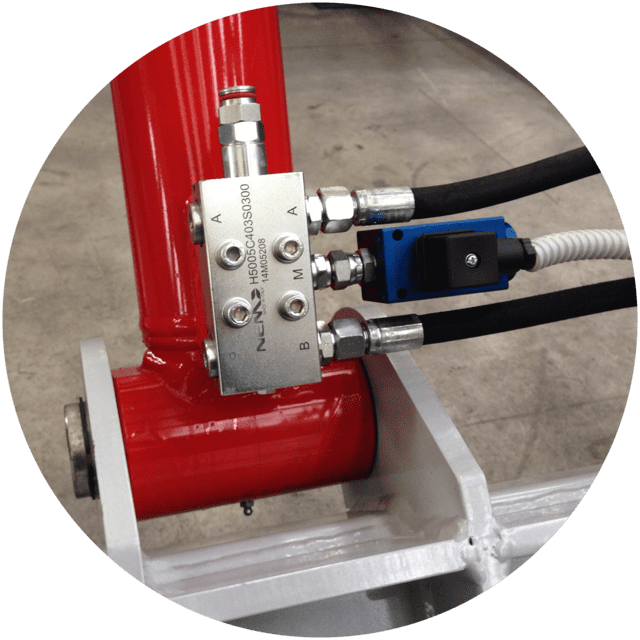

Hydraulic locks - prevents goods lift from any unprompted movement

Hydraulic locks (stop valves) are attached directly onto the cylinder. They eliminate the risk of unprompted rapid decent of the platform even in case of damage to hydraulic hoses and complete or partial loss of pressure in the hydraulic system.

Safe hydraulic unit

The hydraulic station is equipped with Italian made hydraulic components and a quiet electric motor with a capacity of 5.5-15.0 kW (subject to the design requirements).

Reinforced high pressure hydraulic hoses and fittings are manufactured in Italy by “ANCHOR”, and are proven by their utilization in some of the most demanding industrial grade machinery such as the world-famous construction equipment manufacturer CATERPILLAR.

The hydraulic station allows for discreet installation in any suitable and convenient location, at a distance of up to 8-10 m from the lifting platform.

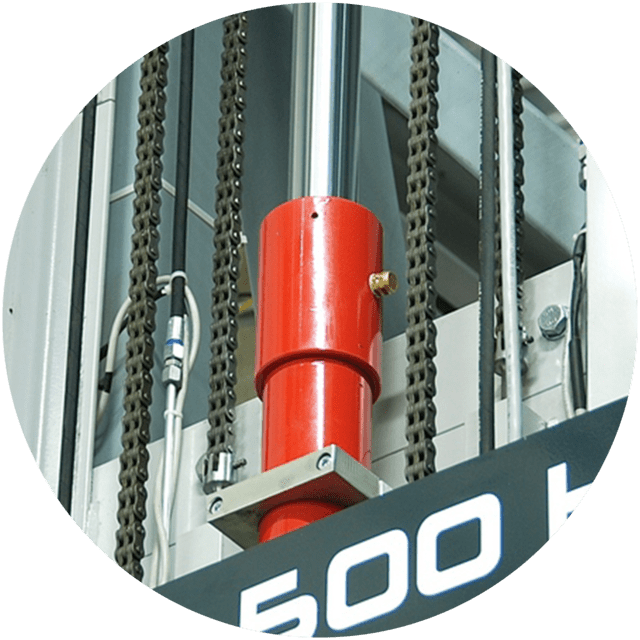

Reliable hydraulic cylinders are an indicator of the goods lift quality

All PANDA LIFT goods lifts are equipped with hydraulic cylinders only from leading specialized manufacturers.

Hydraulic cylinders used on the equipment aren’t serial production, they are produced specifically for your custom goods lift.

Highly durable hydraulic cylinders HydroForce are manufactured in Italy with high quality chrome-plated rods and a rolled (not honed) tube of SIDERGAMMA.

After the reinforcement of the inner layer of metal, rolling (not honing) of the inner surface of the cylinders is performed in order to allow the tolerances of the internal dimensions of the cylinders to correspond to the highest “H8” grade.

The cylinder rod has a solid wear-resistant chrome plating of 25 microns (hardness 900-1100 HV).

All these procedures significantly increase their durability, rigidity and performance. The service life of cylinders is over 700 000 meters of their piston stroke, which approximately equals to 250 000 cycles (lifting / lowering) of the scissor lift.