Differences between scissor and post lifts

Scissor lifts

Invented relatively recently scissor lifts quickly became one of the most popular lifting devices used in construction, manufacturing, repairs and many other fields. Scissor mechanism otherwise called a pantograph utilize one or a series of linked “X” crisscross pattern folding arms which extend and compress to vertically move the platform. In many areas scissor lifts are an irreplaceable solution, however they have several fundamental limitations, which could make another type of lift a better alternative. Let us look into that more closely:

To reach higher, you would need to stack multiple “X’s” on top of each other. And whereas this method is widely used in mobile lifts and lifts with small platform sizes and load capacities, there are extra design features to be considered when using this scheme for heavy loads and large platform sizes.

Why?

Scissor arms are connected to each other with rotatably mounted pins allowing two arms to move around it. Adding weight stresses the pivot which causes what is known elastic (temporary) deformation which further compresses arms. The effect is minimal in a single scissor mechanism which only has two such pivots. However, with multiple scissor X’s on top of one another the structure becomes less stiff, particularly under heavy or uneven (off center) loads. This is especially important for large platforms if a car or forklift is entering or exiting lift at its highest position. Add to that the gradual wear out of pivot pins and bushings with time you may end up with a shaky structure.

As a general rule, if you are looking to lift either heavy loads or have a large platform and a scissor lift would require more than 2 X’s in its structure, you should consider post(column) lifts.

Further loading factors affecting scissor lift performance such as static edge loads, rolling axle, sliding loads etc. are covered in the following article:

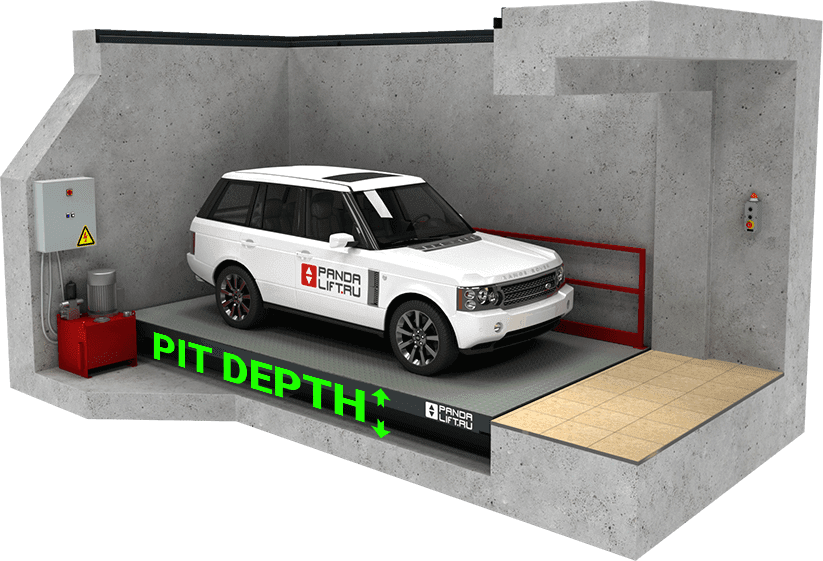

What is the required pit depth?

As opposed to column lifts, scissor lifts require a pit (space under platform) to stow arms underneath. For example, a regular single scissor car lifts require between 600-750 mm whereas lifts with multiple X’s require anywhere from 900 mm and higher.

How high can scissor lifts go? How many X’s will my scissor lift have?

You could calculate maximum height a standard scissor lift could reach by applying a simple formula: multiply the length of the platform by the amount of X’s in its structure and by a factor of 0,65.

H = L * X * 0,65. In example for a standard car single scissor lift with 6m platform length the maximum potential height would be H = 6000 mm * 1 * 0,65. In this case lift could travel to a maximum height of 3900mm or 3,9 meters. Consequently, to go higher with the same platform, you would need extra “X”s.

Post (column) lifts

Post lifts as the name suggests are made with fixed steel columns with vertically positioned hydraulic cylinders inside them which push the platform up. Apart from being more costly and needing to accommodate posts next to the platform (which eats up space) column lifts have little drawbacks as opposed to scissor lifts.

In comparison their main advantages are:

+ Higher achievable lifting height for the same platform dimensions

+ Shallower pit

+ Better uneven (off center) load resistance

+ Longer service life due to lack of movable joints

Energy efficiency

Column lifts are much more energy efficient because of their vertical cylinder placement. This allows them to apply only the force required to push the weight upwards, without any side component as opposed to scissor hydraulic cylinders near horizontal position at start.